Products

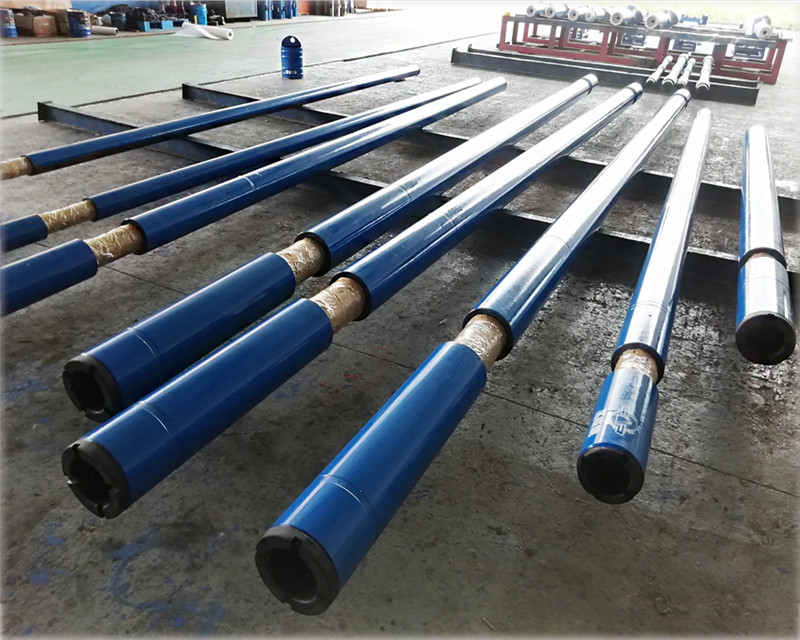

Hydraulic double acting Type Shock sub

Product type

MECHANICAL-HYDRAULIC SHOCK SUB

mechanical-hydraulic shock absorber is a new type double acting shock absorber, it absorbs jumping and shaking of drilling tools through compressed energy storage from two kinds of damping elastic elements which are disc spring and silicone oil, it has advantages of good maintainability, high load resistance and long service life etc. It can be suitable with different formation and provide the best protection for drill bits and drilling tools, and High temperature products (180oC) can also be provided according to user’s requirement.

DOUBLE WAY HYDRAULIC SHOCK SUB

double way hydraulic shock absorber is a kind of shock absorber which can slow down or eliminate shock both in vertical and axial direction. This tool can keep the normal bit pressure and torque, therefore it can reduce the damage of drill bit, drilling tools and ground equipment due to shock, to achieve the purpose of improving drilling rate and reducing the drilling costs.

MECHANICAL SHOCK SUB

shock absorber is a shock tool act as vertical absorbing function when drilling with cone bit or abrasive coring bit. It can absorb or slow down vertical shocking and impact load of drill stem while drilling, thereby keep normal drilling pressure, prolong service life of drill bit, protect drilling tools and surface equipment, decrease drilling cost and increase drilling efficiency.

shock absorber use butterfly spring as elastic element, this is quite different with hydraulic shock absorber which use silicon oil etc., As working medium, its working property do not effect by working circumstance, it has the advantages of simple structure, reliable working, convenient operation, maintenance, good shock absorption, long service life and high property.

HYDRAULIC SHOCK SUB

hydraulic shock absorber can use its inner compressible liquid to absorb or reduce impact and shock load on drill bit and drilling tools whiledrilling, so it is a kind of tool which can protect drill bit teeth, bearings and drilling tools, to prolong the service life of drill bit and drilling tools.

Technical parameter

| OD | ID | Tool Joint | Max. Tensile Load | Max. Drill Pressure | Max. WorkingTorque | Max. Stroke |

| Connection | (Lbf) | (Lbf) | (Lbf-ft) | (in) | ||

| 4 3/4'' | 1 1/2'' | 3 1/2 REG | 220,320 | 89,920 | 7,370 | 4'' |

| 6 1/4'' | 2'' | NC46 | 337,230 | 134,890 | 10,840 | 4 3/4'' |

| 7'' | 2 1/4'' | NC56 | 337,230 | 134,480 | 10,840 | 4 3/4'' |

| 8'' | 2 13/16 | 2 13/16 | 449,640 | 157,370 | 14,450 | 5 1/2'' |

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141