Products

API 7-1 Casing Section milling tool

Product profile

Section mill is a kind of casing window opening tool which integrates casing cutting and milling functions. The section mill runs into the casing along with BHA, and cuts the casing at designated position first. After casing is completely cut off, It will be directly milled from this position. After reaching a certain depth, the casing window opening task is completed. section mill has the advantages of simple structure, convenient operation to make it a very effective casing window opening tool.

Meanwhile, section mill can squeeze and inject cement in well abandonment operation, which can make cement directly contact with the formation in a long distance within 360 degrees. The cement can enter the reservoir according to the existing porosity and fractures of the formation, and the plugging effect is far better than that of squeezing cement after perforation.

Working principle

After section mill is lowered to the designated position in the casing along with BHA,start the rotary table, turn on the pump, the piston in the tool is pushed downward by the pressure, the lower cone of piston pushes the cutting blades open and repair the open hole. When the cutting blades open to the maximum diameter, the open hole repairing is finished. Under the continuous pump pressure, the blade can be opened and reamed the hole directly. After the pump is stopped, the piston is reset under action of spring and the cutting blades will be automatically retracted.

Product features

(1) Mechanical design, simple structure and easy operation

(2) Low start-up pressure and large blade support force are helpful for casing cutting;

(3) High strength spring design helps to automatically retract the cutter after cutting;

(4) The design of stop block and pin is helpful to force tool retraction;

(5) The blade has large expansion and can be applied to the same casing with different wall thickness;

(6) The blade is made of high quality tungsten carbide and Bake hughes same welding process, with high cutting efficiency and long service life.

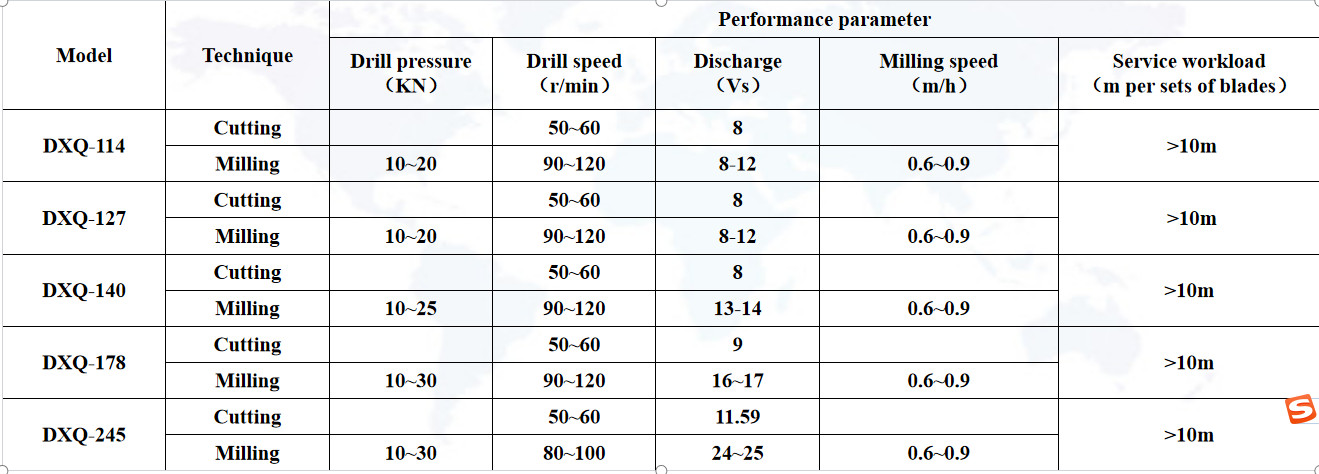

Section mill-Size table

Matching tools - High class taper mill

Milling tools are all made of high quality tungsten carbide alloy and Baker Hughes same welding technology. The purpose of this series of mills is to completely restore the material selection, structure design and welding process of Baker Hughes, so as to achieve the same product quality of Baker Hughes.

2.High class tap mill profile

can produce high class taper mill with an outer diameter of 76 mm to 445 mm. The high-quality alloy steel is used as the main body, allowing the processing of large-size water holes to ensure the smooth discharge of milling debris. At the same time, according to the specific needs of customers, the product structure can be designed to achieve the best use performance.

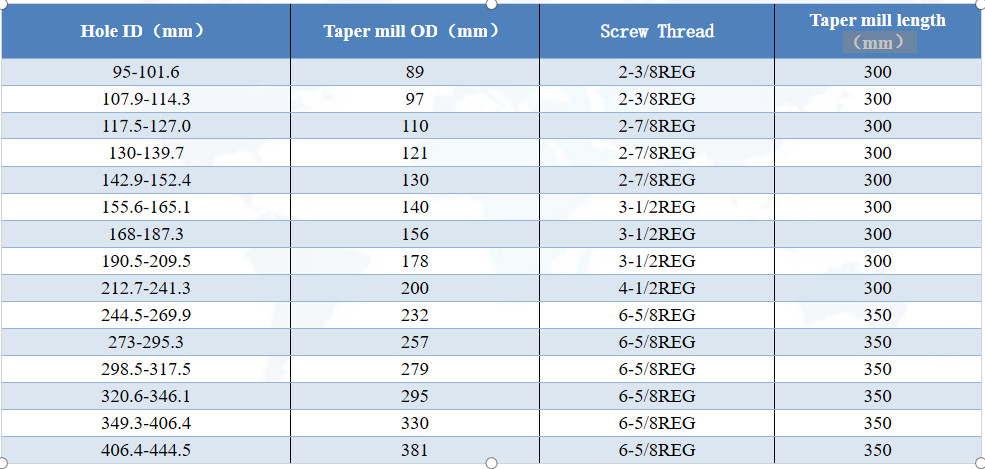

3.Taper mill-Size table

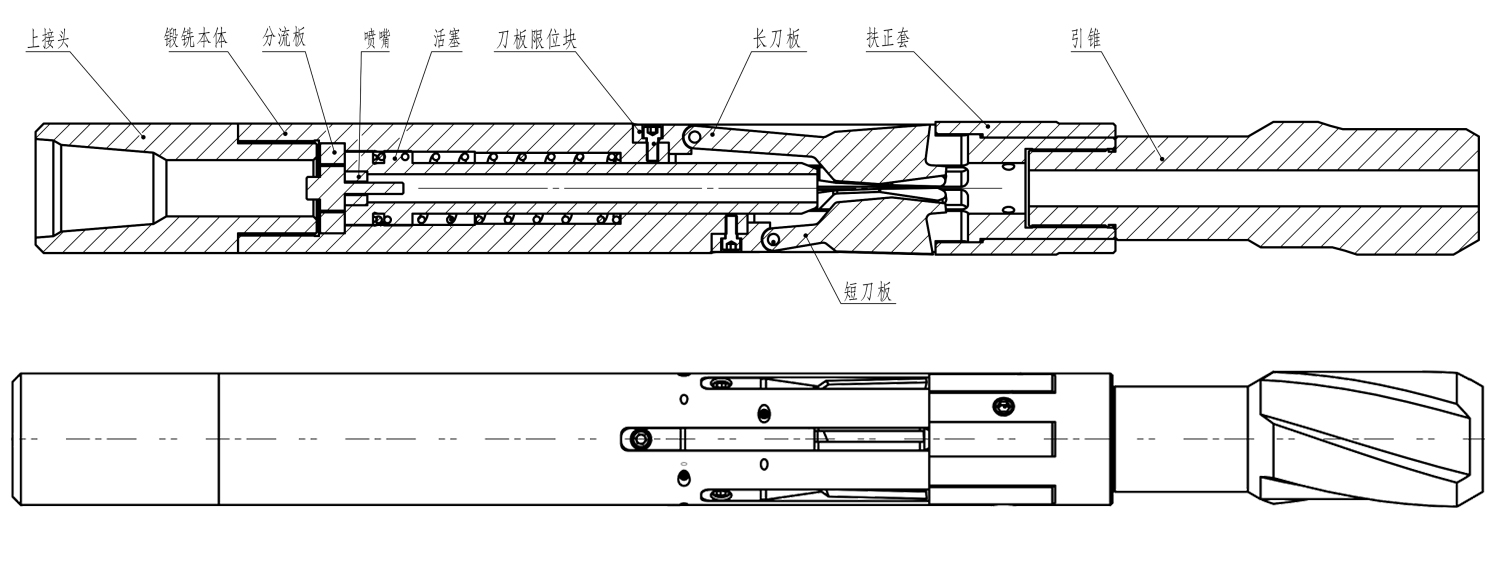

Product structure

1. Section mill mainly includes the following parts: upper joint, main body, piston, nozzle, cutting blades and guide cone, etc.

III.Technical advantages of Petrozhr section mill

1.Produced with high quality tungsten carbide

The section mill blades produced by our company have the following advantages:

(1) Milling and cutting operations are faster than ordinary blades;

(2) Reduce the drilling pressure required for cutting;

(3) The tooth marks are even and no step surface is produced;

(4) The debris produced is more uniform;

(5) The hardness of raw materials is higher and the structure is reasonable. When working, it is cutting metal rather than grinding metal.

2.Strict raw material inspection

The tungsten carbide selected by our company will be sent to the professional testing agency for inspection after each batch arrives.To ensure that the alloy hardness and other indicators meet the company's production requirements

3.Perfect welding process

We employs former Baker Hughes senior welder and selects the same welding tools and auxiliary materials in Baker Hughes workshop to realize the reproduction of Becker welding technology in process and equipment.

In order to reduce the deformation of tools due to thermal changes before and after welding, we establishes welding insulation system to ensure the stability of product geometry and work efficiency.

IV.Section mill operation procedure

Wellhole preparation:

1. Repair casing. Repair downhole casing with taper mill or casing shaper.

2. Well Cleaning. Wash out crude oil or other liquids from the well with clean water.

3. Scraping casing or wellbore. Pipe scraping and drifting shall be carried out with standard scraper and drift diameter to 20 meters below the section milling position.

4. Prepare the milling fluid. Its various properties can ensure stable carrying capacity to iron debris.

Ground test:

1. Test the reliability of tools;

2. The change of pump pressure is tested when the cutting blades is opened, which provides the basis for judging whether the downhole casing is completely cut off.

Milling position selection:

1. The cement outside the section milling casing should be well cemented.

2. Avoid the position where the casing has dislocation and deformation. If there is such a position, the operation should be carried out 30-40m above the position.And the starting point of cutting operation shall be 1-3m above the nearest coupling.

3. The pocket should be reserved under the shaft. Generally, the length of the pocket should be greater than 100m.

Cutting casing:

① After connecting the tool into BHA and running down to the section mill position, start the rotary table to determine the casing coupling position according to the casing (logging) record, and lower the tool to about 1-3m above the nearest coupling and brake.

② Start the rotary table first, increase the rotating speed to 50-60r / min, start the pump, gradually increase the displacement, so that the pump pressure increases. At this time, the pump pressure increases from small to large, gradually increasing to 10-12mpa.

③ Continue to cut the casing for 20-45min. When the pump pressure drops suddenly by 2-5mpa, the casing is cut off. In order to make the cutter body fully open, keep the cutting position at this position for 30min after cutting, and gradually increase the displacement to ensure the full formation of fracture

Milling casing:

The WOB can be increased gradually after the casing is cut off. which is controlled between 10-25kn, the rotary speed is increased to 80-120r / min, and the pump pressure is controlled within 10MPa to ensure that the circulating displacement can carry iron debris. When each section is about 0.5m, it can be drilled 1m for one reaming and circulation, so as to facilitate the iron debris milled from the section to return smoothly through the annulus. After 1-2 cycle cycles, drill in again to continue forging and milling.

[In the process, it is necessary to properly adjust the mud performance while increasing the displacement; at the same time, properly move the drilling tool and adjust the circulation to make the iron chips fully return and prevent debris accumulation]

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141