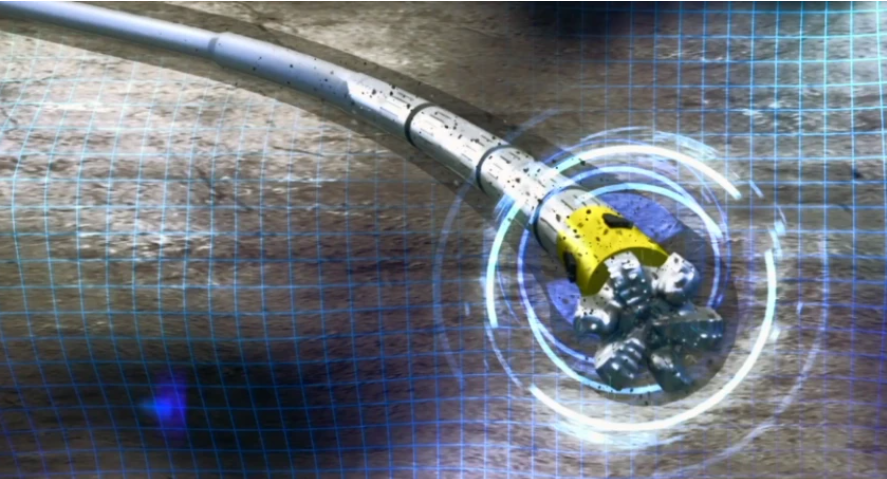

rotary steerable system (RSS) is a form of drilling technology used in directional drilling. It employs the use of specialized downhole equipment to replace conventional directional tools such as mud motors.It is a major change in directional drilling technology since the 1990s.

RSS drilling has the characteristics of low friction and torsional resistance, high drilling rate, low cost, short well construction period, smooth wellbore trajectory, easy control and extension of horizontal section length, etc., which is considered as the development direction of modern directional drilling technology.

The rotary steering system can be divided into two kinds of systems according to its guiding mode: Push the Bit and Point the Bit.

More than 40% of the world's directional Wells are drilled using rotary steerable systems, which have the advantage of real-time control of downhole drilling direction, similar to the "3D version of the snake" drilling tool trajectory adjustment. This allows a single trip through the target formation in a "three-dimensional" zone - even a 0.2 m diameter bit can be traversed laterally or diagonally through a thin 0.7 m reservoir to achieve a long "lateral" travel of 1,000 m in a single trip.

Due to the relatively high cost of the technology, limited progress has been made in the lower end of the directional drilling market. However, accurate guidance is of great value to maximize the exploitation of oil and gas resources.

Post time: Jul-14-2023

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141