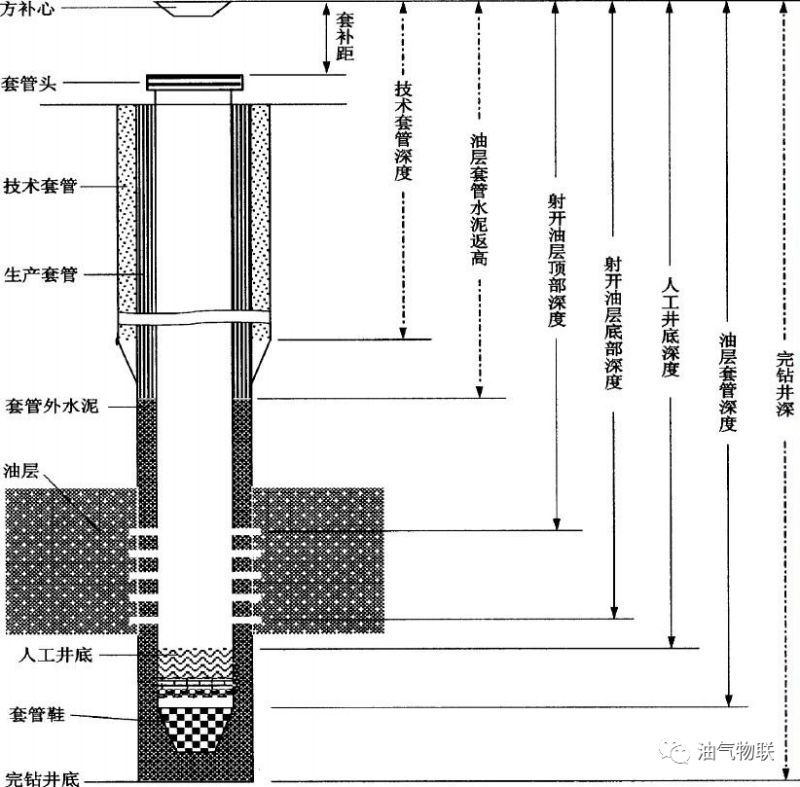

The well structure refers to the drilling depth and the bit diameter of the corresponding well section, the number of casing layers, diameter and depth, the cement return height outside each casing layer and the artificial bottom hole.

Composition of well structure:

1.Conductor

The first casing in the well structure near the open hole wall is called the conduit. functions: to protect the surface near the well head from being washed out at the beginning of drilling, to establish the mud circulation, to guide the drilling tool, to ensure the vertical drilling of the hole, etc.

2. Surface casing

The second casing in the well structure is called surface casing. The function is to seal the water layer, strengthen the wall of the upper loose rock, protect the hole and install the packer.

3. Technical casing

A layer of casing inserted inside the surface casing is called the technical casing. The function is to protect and seal off the difficult and complex formation above the reservoir to ensure smooth drilling.

4. Oil layer casing

The last layer of casing in the oil well is called oil layer casing, referred to as casing. The function of is to strengthen the well wall of oil reservoir, seal off the oil, gas and water layers,and ensure the production of oil well for a long time.

5. Cementing

Cementing is a process by which cement slurry is injected into the annular space between the casing and the well wall. Its function is to strengthen the well wall, protect the casing, and seal off each oil, gas and water layer in the well so that they do not collude with each other.

6. Cement sheath

After finishing all kinds of casing and cementing, a solid cement ring cylinder is formed in the annular space between casing and well wall, which is called cementing cement ring. Its function is to seal the formation, strengthen the well wall and protect the casing.

7. Master bushing

In rotary drilling, a part of the kelly pipe is stuck in the middle of a turntable that spins downhole tools.

8. Complete drilling depth

The completion drilling depth is refers to the height from the bottom of the open hole to the top of the bushing surface of the rotary table.

9. Casing depth

Casing depth refers to the depth between the upper surface of the rotating table and the position of the casing shoe of the oil formation.

10. Artificial well bottom

The top surface of an oil well that remains in the casing after cement has set in the lowermost section of the casing. The artificial bottom hole depth is expressed by the depth of the distance from the top surface of the rotary table to the artificial bottom hole.

11. High cement return

The height of the cement return in the annular space between the casing and the wellbore. The depth of the cement return is equal to the distance between the upper surface of the turntable and the cement surface of the annular space.

12. Cement plug

After cementing, the cement column from the bottom of the drilled well to the bottom of the artificial well is the cement plug.

Post time: Oct-07-2023

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141