Dissolvable bridge plug is made of new material, which is used as temporary wellbore sealing segmentation tool for horizontal well fracturing and reforming.

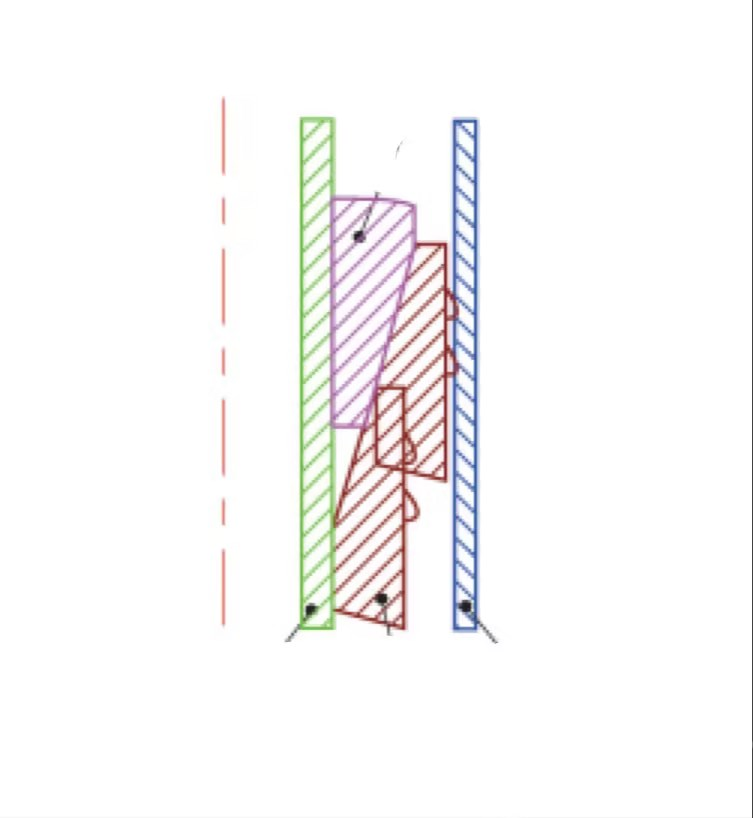

Dissolvable bridge plug is mainly composed of 3 parts: bridge plug body, anchoring mechanism and seals. The bridge plug body is made of high-strength dissolvable material, including the center tube, cone, protection ring and joints. The anchoring mechanism is made of dissovable material as the carrier, and the surface is treated with alloy powder, alloy particles or ceramic particles. The seals are dissovable rubber or plastic.

1.Components of dissovable bridge plugs

Dissolvable bridge plugs are mainly made of high-strength magnesium-aluminum alloy or polymer material processing. Magnesium-aluminum alloy is mainly composed of magnesium, with low density (about 1.8~2.0g/cm³), and at the same time, its chemical activity is high, so it is easy to be dissolved in the humid environment.

The dissolution rate of magnesium-aluminum alloy is mainly related to the liquid temperature and Cl-concentration, the higher the temperature, the faster the dissolution; the higher the Cl-concentration, the faster the passivation film on the alloy surface destroys, the better the conductivity of the liquid, the faster the dissolution rate.

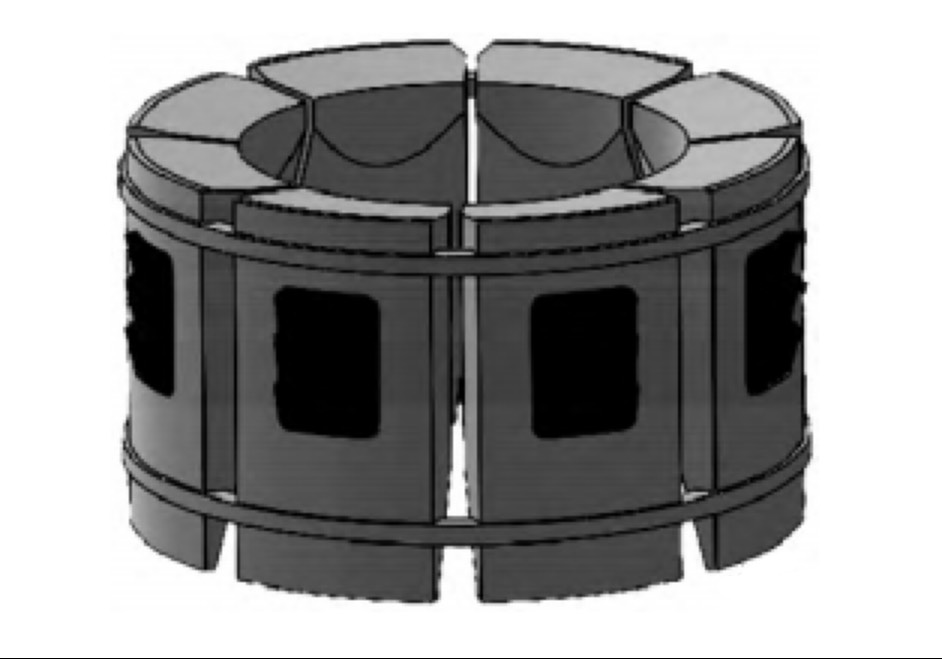

2.Dissovable bridge plug anchoring mechanism

Dissovable bridge plug anchoring tile is different from the common cast iron tile and composite tile, in addition to the need to provide reliable casing anchoring force and cylinder locking force, but also must have a good dissolution performance and the ability to return to the discharge.

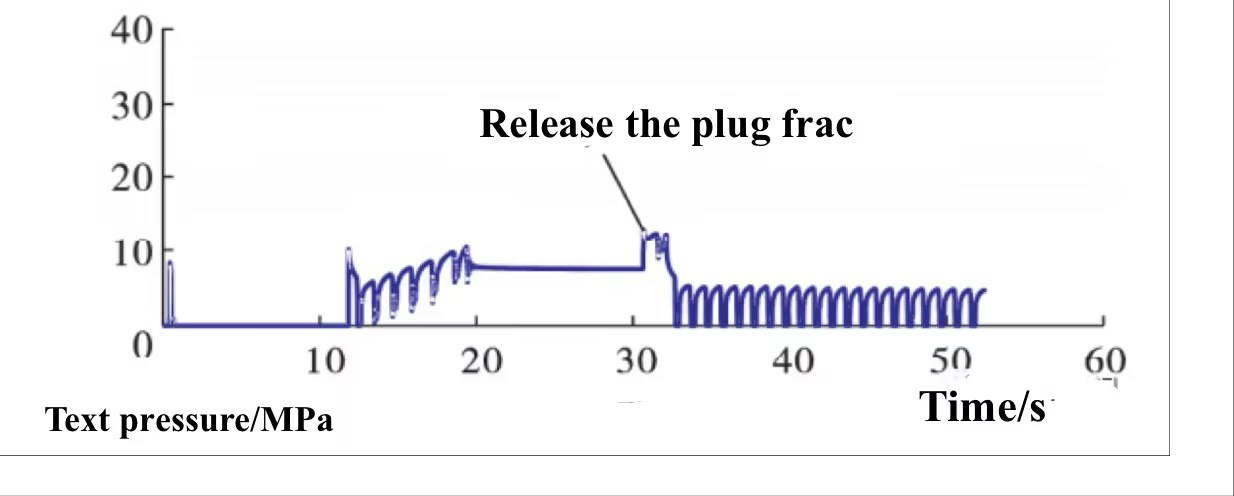

3.Dissolvable Bridge Plug Seat Seal Release Value

Baker 20 # hydraulic seating tool will be dissovable bridge plug seated in the casing tooling, the test process of the bridge plug and seating tool is well-matched, the bridge plug is successfully seated and lost hand, the loss of hand pressure of 12.3MPa (equivalent loss of hand force of about 155kN) seated hand curve as shown in the figure.

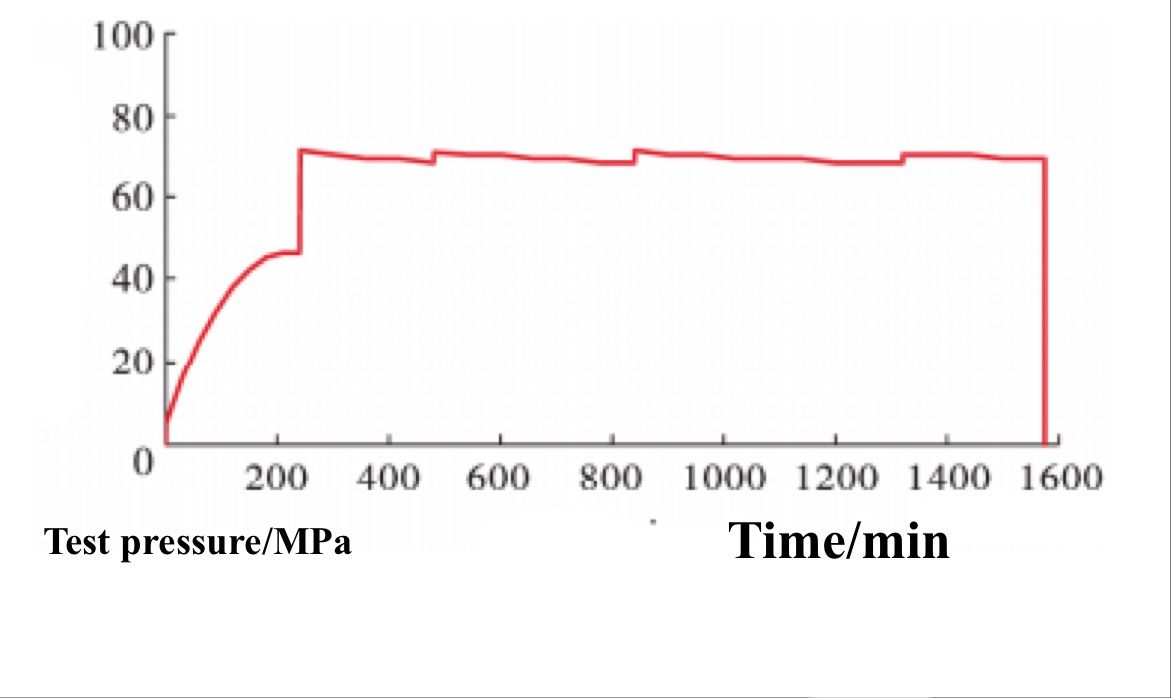

4.Pressure sealing performance of dissovable bridge plug

In order to verify the high-temperature pressure sealing performance of the dissovable bridge plug, the casing worker was installed in a high-temperature experimental device and heated to 93°C. After the temperature stabilized, the pressure was slowly increased to 70 MPa. The pressure was stabilized for 24 hours and then maintained for 15 minutes. There is an obvious pressure drop and the pressure test curve is shown in the figure. The test results show that the pressure sealing performance of the bridge plug can meet the requirements of on-site fracturing construction.

5.Working time of dissovable bridge plug

The working time limit is the time interval from when the bridge plug is inserted into the well to fracturing. According to the existing shale gas construction model, the working time limit of the dissovable bridge plug is 24 hours, which can meet the needs of on-site construction of shale gas wells, that is, from the time when the dissovable bridge plug is inserted into the well Starting from hour, fracturing construction can be carried out within 24 hours. Any performance test for dissovable bridge plugs can be conducted with reference to the 24-hour working time limit.

Post time: Sep-22-2023

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141