-

What are the main causes of blowout accidents in drilling operations?

Blowout is a phenomenon in which the pressure of formation fluid (oil, natural gas, water, etc.) is greater than the pressure in the well during the drilling process, and a large amount of it pours into the well-bore and ejects uncontro...Read more -

To our Egypt Clients

Our Clients have ordered three generators.Landrill have arranged the shipment of GENLITEC SILENT GENERATOR last week. The three g...Read more -

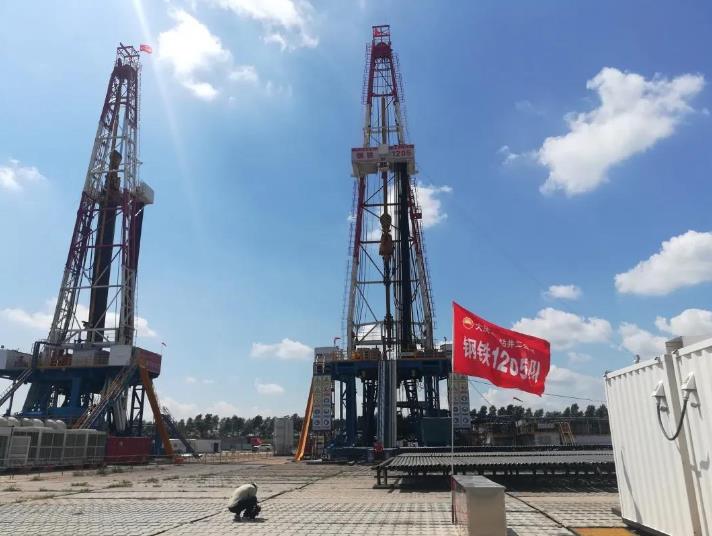

One of the highest drilling difficulty in the world

At 10:30 on July 20, CNPC Shendi Chuanke 1 well, the most difficult drilling well in the world, started drilling in the Sichuan Basin. Prior to that, on May 30, CNPC Deepland Tako 1 well was drilled in the Tarim Basin. One north and one...Read more -

Classification of pump and control of pump barrel leakage

1. Classification of pump (1)tubing pump Tubular pump, also known as tubing pump, is characterized by the outer cylinder, bushing and suction valve assembled on the ground and connected to the lower part of the tubing first into the well, and then the piston equipped with the discharge valve is l...Read more -

What does downhole operation include(1)?

1.What is downhole operation? Downhole operation is a technical means to ensure the normal production of oil and water wells in the process of oilfield exploration and development. Oil and natural gas buri...Read more -

Landrill Oil Tools held an activity:Environmental Protection

With the development of society, Environment is getting worse and worse, and the earth bear the big burden, so Landrill organized an activity last week to try our best to protect the earth. ...Read more -

Factors of paraffin formation in oil Wells and methods of paraffin removal

The fundamental reason why oil Wells wax during production is that the crude oil produced by oil Wells contains wax. 1.Factors of paraffin formation in oil Wells (1) Composition and temperature of crude oil Under the same temperature condition, the solubility of light oil to wax is greater than t...Read more -

Links

01 The type and function of the hanging ring The hanging ring can be divided into single-arm hanging ring and double-arm hanging ring according to the structure. Its main function is to suspend the hanger to hold the drill when the drill is pulled down. Such as DH150, SH250, where D represents si...Read more -

Top ten well completion tools

The types of downhole tools commonly used in offshore oil field completion and production strings include: Packer, SSSV, Sliding Sleev , (Nipple), Side Pocket Mandrel, Seating Nipple, Flow Coupling, Blast joint, Test Valve, Drain Valve, Mandrel, Plug, etc. 1.Packers The packer is one of th...Read more -

Past and present for Cone bit

Since the advent of the first cone bit in 1909, the cone bit has been the most widely used in the world. Tricone bit is the most common drill bit used in rotary drilling operations. This type of drill has different tooth designs and bearing junction types, so it can be adapted to various formatio...Read more -

How should the drill pipe be maintained after use?

After the drilling operation is completed, the drill tools are neatly placed on the drill pipe rack according to different specifications, wall thickness, water hole size, steel grade and classification grade, need to rinse ,blow dry the inner and outer surfaces of the drill tool, joint threads, ...Read more -

Surface treatment of downhole motor- the successful solution to the corrosion in saturated brine

1. Successfully solved the corrosion problem in saturated brine. Processing method comparison: a. Chromium plating is the most widely used method at present. 90% of domestic petroleum customers use this method, which has a short service life and low price. The biggest problem of electroplating is...Read more

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141