1.The main types of jars used are drilling jars, fishing jars and surface jars.

The drilling jar shall be designed in the drill string assembly to be able to jar and release the jam at any time if it occurs during drilling or tripping.

Fishing jar, only need to be unstuck to the well operation, can not work long time while drilling.

The ground jar is only used at the wellhead, and its vibration effect on the stuck point is downward jar, which is more convenient to use in the field.

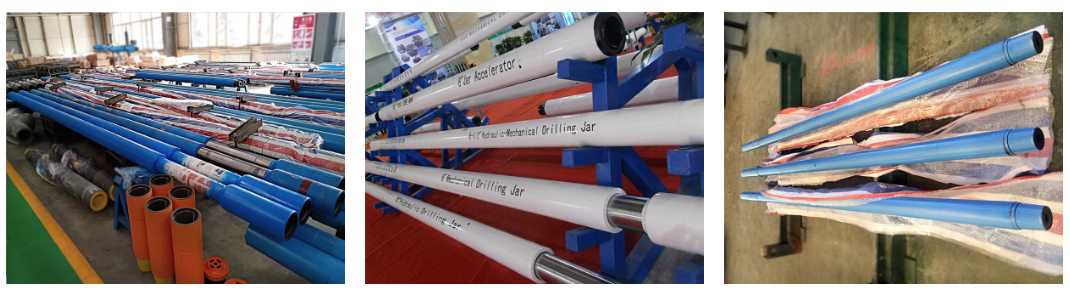

2.The structure types of jar mainly include mechanical type, hydraulic type and Mechanical -hydraulic type.

2.1. Mechanical jar, using the principle of mechanical friction, the locking mechanism adopts a set of rib-type slips, the release of slips is controlled by the deformation of the elastic sleeve under the action of pressure, and the jar force is not affected by the temperature in the well. The mechanical jar can be designed with adjustable or non-adjustable jar force. The jar force of the adjustable jar is adjusted at the wellhead, and the jar force of the non-adjustable jar is set during product assembly and cannot be adjusted on site, but the length of the whole machine is short and the work is safe and reliable. Mechanical jar has high requirements on metal materials, heat treatment and machining accuracy.

2.2. Hydraulic jar, using the damping effect of hydraulic oil flowing in the small flow channel as a locking mechanism, using the release caused by sudden changes in the flow channel to produce a blow in the jar, thus forming a vibration in the drill string. Due to the limitation of the working principle of its locking mechanism, the hydraulic jar can only produce a jolt in a single direction, generally upward. Due to the long delay function superior to the mechanical jar, the jar force can be adjusted arbitrarily by the driller’s operation. However, because the hydraulic medium, sealing material and sealing structure are easily affected by wear, well temperature and other factors, the life, adaptability and reliability of the product are unstable. Obviously, this kind of jar has very strict requirements on the design of sealing structure and the selection of sealing materials, as well as the machining accuracy of parts.

2.3. Double-Acting Hydraulic Mechanical Drilling Jar,concentrated the advantages of the above two jar principles, even if the hydraulic delay jar failure, the mechanical jar can continue to be used, the technical performance has been greatly improved, in line with the future jar product development direction.

Jar products are of great significance to drilling operations. The correct selection and use of jar products can bring into full play their due efficiency and bring greater economic benefits to drilling industry.

3.The use of the jar

Drilling jar is a downhole tool that delivers an axial impact load to the stuck point of a drill string. Jars are often the first line of defense against stuck pipe and can save operators from costly fishing and remedial operations by quickly “jarring” the string free.

Contact :Junnie Liu

Mobile/Whatsapp:+0086-158 7765 8727

Email: [email protected]

Web: www.landrilltools.com

Post time: Dec-12-2024

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141