Products

API 7-1 Drilling String Valves

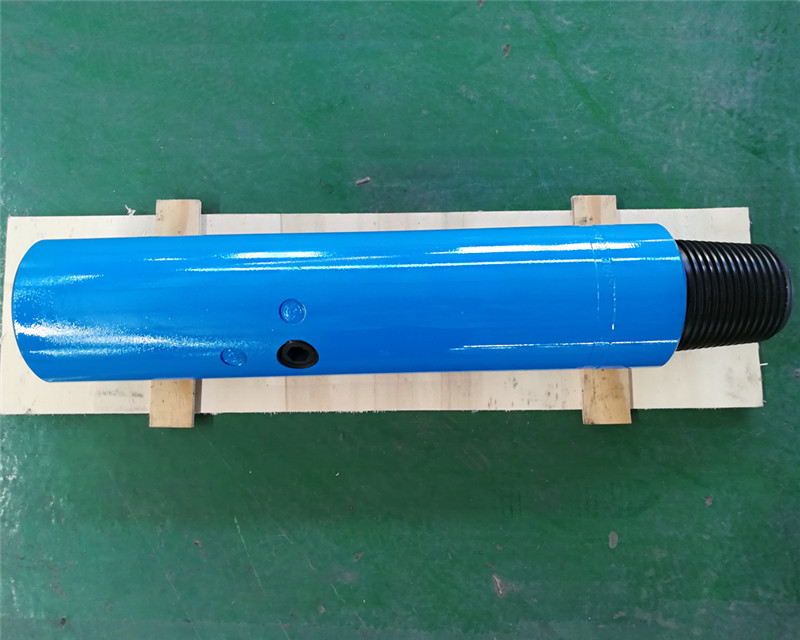

Full Opening Safety Valve (FOSV)

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

When ordering please specify:

Connection.

O.D. and I.D.

Working Pressure: 5,000 / 10,000 / 15,000 PSI;

Kelly valve

Kelly valve is also named Kelly cock or Gray valve. It is a hand control valve in drill string circulating system and it is one of the effective tools to prevent blowout. Kelly valve is divided into Upper Kelly Valve and Lower Kelly Valve. Upper Kelly Valve is connected with swivel sub and Kelly. Lower Kelly valve is connected with lower end of Kelly and top of drill pipe or lower end of Kelly save sub. Rotating the wrench of full opening safety valve 90° to realize on and off. In the drilling operation, in order to avoid malignant accidents, Kelly valves should be connected to both ends of Kelly to prevent loss of drilling flid and blowout. Kelly cock valve, which is a manually operated ball valve run in I.D. of drill string, It is one of effective tool for preventation from blowout.

The kelly cock is divided into upper kelly cock valve and lower kelly cock.

The upper kelly cock is connected with lower end of swivel and upper end of kelly. The lower kelly cock is connected with upper end of drill pipe and lower end of kelly or connected between lower end of kelly saver subs.

The kelly cock features a simple operation,the kelly cock can be Turened on or Turened off by only turning the special operationg spanner at 90 degrees according to indicating direction. During drilling operation the kelly cock shall be connected at upper end and lower end of kelly.

When ordering please specify:

Upper or Lower type;

Tool OD;

Working Pressure: 5,000 / 10,000 / 15,000 PSI;

Tool connection.

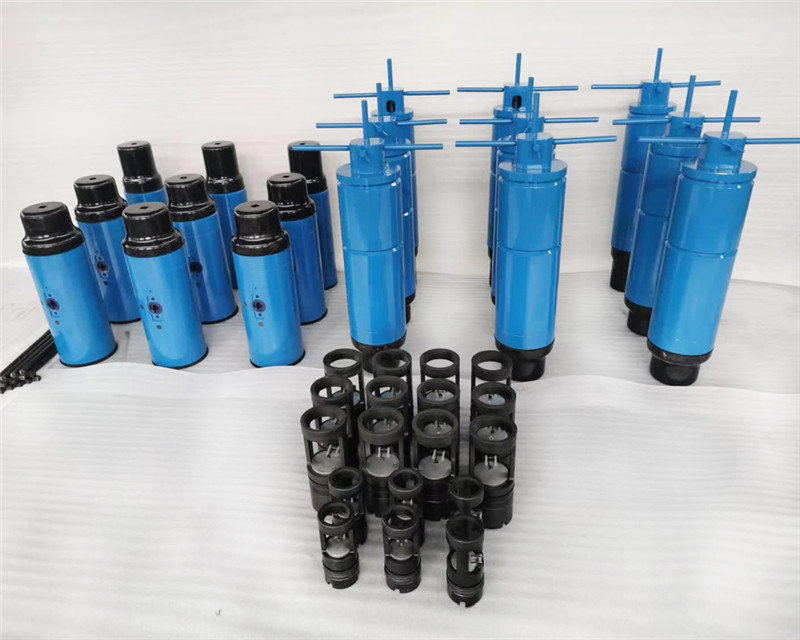

Inside BOP

Inside blowout preventer (Inside BOP) is a special tool, which can be striped through the BOP preempt to be connected with the added drilling tools as soon as possible, when the blowout is happened during lifting the drilling tools, the inside blowout preventer has many advantages such as high-pressure, sealed reliable, easy to operate, switch quickly and so on.

When ordering please specify:

Tool OD;

Working Pressure: 5,000 / 10,000 / 15,000 PSI;

Tool connection.

During the drill tool is coming out of hole, the blowout is happened because of suction result, When the fluid, oil, steam or water comes out from discharged drill pipe, the inside blowout preventer should be quickly connected to the drill pipe, The inside blowout preventer can be easily connected to the drill pipe due to the fact that the valve of blowout preventer is at open position and the fluid in down hole can flow out of inside blowout preventer is at open position and the fluid in down hole can flow out of inside blowout preventer, The relief rod can close the valve by screwing out the locking bolt, right now, the inside blowout preventer allows the fluid to be pumped in hole from top to bottom, but the in hole fluid is not able to flow into drill string and finally flow out of inside blowout preventer Then the purpose of blowout prevention van be reached by the following steps, Discharge the relief sub regulate the fluid and start the pump circulation.

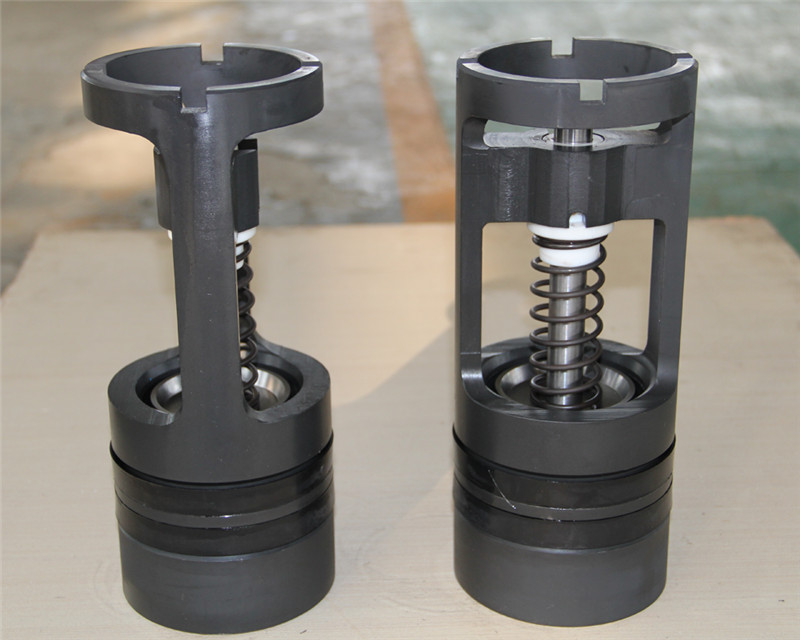

Drop-in check valve

Drop-In Check Valves prevent return flow during a kick and are suitable for most drilling situations in which return flow through the drill string is a risk and normal operation requires the benefits of a full-bore sub. By preventing upward flow through the drill pipe, but allowing fluid to be pumped downward to circulate the well, the valves provide the driller with the means to control the drill pipe pressures when required, significantly improving and simplifying well control.

When blowout is going to be happened,the thread connections of the kelly is screw out immediately and put the check valve is into the drill pipe and then pumped downward to the required place.Thus the blowout can be prevented.

When ordering please specify

Smallest bore in drill string through which the check valve must pass.

Landing sub connection size and type.

Outside diameter of mating tool joints.

Float valve

The float valve prevents drilling fluids, cuttings and metal debris from flowing back up the drill string. When correctly installed on the drill string these valves provide added blowout prevention.

The float valve can be used anywhere from top to bottom of the drillstring. It's most common location is in the BHA (bottom hole assembly) which includes the bit, and can include a bit sub, near bit stabilizer, other stabilizers, float sub, cross-over sub, mud motor (top sub), drill collar, and the drillpipe. Multiple float valves can be used in one string, although double stacking is not recommended because of possible damage to the float valve in high pressure situations. Instead, separate the valves in different tool joints.

Drill Pipe (DP) Float valves are available for standard service, H2S – 300°F service (HNBR/HSN) and H2S – 400°F service (Viton.)

Model F, FA:1R, 1F2R, 2F3R, 3F, 3½ IF, 4R, 4F, 5R, 5F6R, and 6F

Model G,GA, GC:1F2R, 2F3R, 3F, 3½ IF, 4R, 4F, 5R and 5F6R

When ordering please specify:

Float valve type (Model F or Model G);

Float valve size;

Connection and O.D of sub.

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141