Products

API 6A Wellhead manifold Check Valves

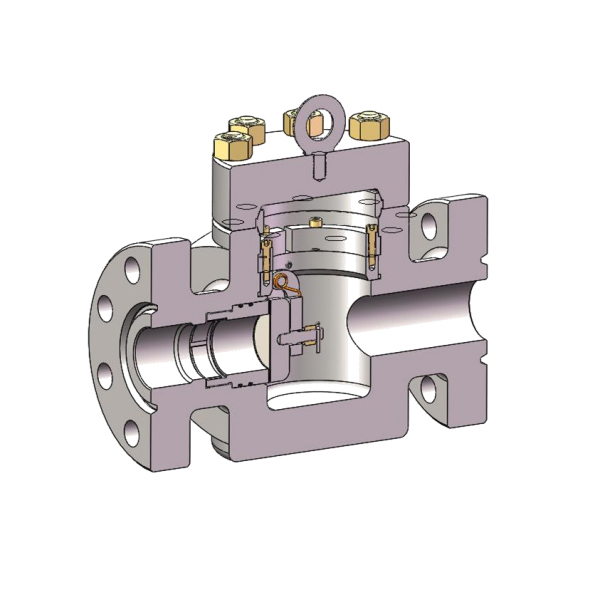

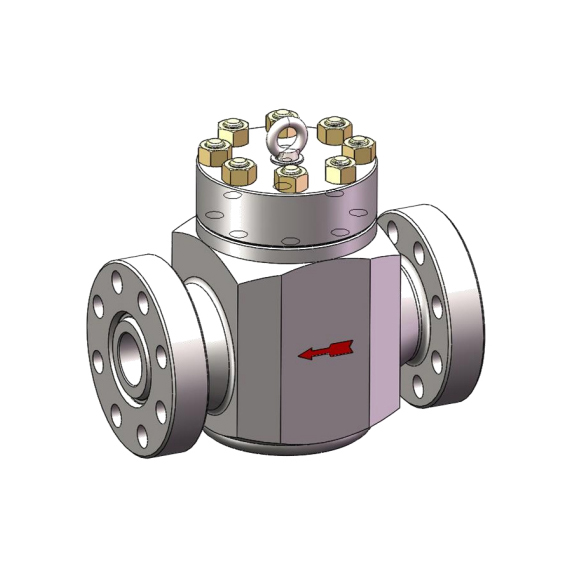

Swing type

The swing check valve adopts a built-in rocker arm swing structure, and all opening and closing parts of the valve are installed inside the valve body.

It does not penetrate the valve body, except for the sealing gasket and sealing ring for the middle flange part, there is no leakage point as a whole, eliminating the valve

External leakage. The swing check valve rocker arm and disc connection are spherical so that the disc is in a 360-degree range

There is a certain degree of freedom inside, and there is appropriate micro position compensation.

Swing check valves are fully open and the fluid pressure is almost unimpeded and passes through the pressure of the valve

The drop is relatively small.

It is suitable for clean media, not suitable for media containing solid particles and large viscosity.

The disc of the swing check valve rotates around the rotating axis. Its fluid resistance is generally less than that of lifting check valves,

Suitable for larger caliber applications.

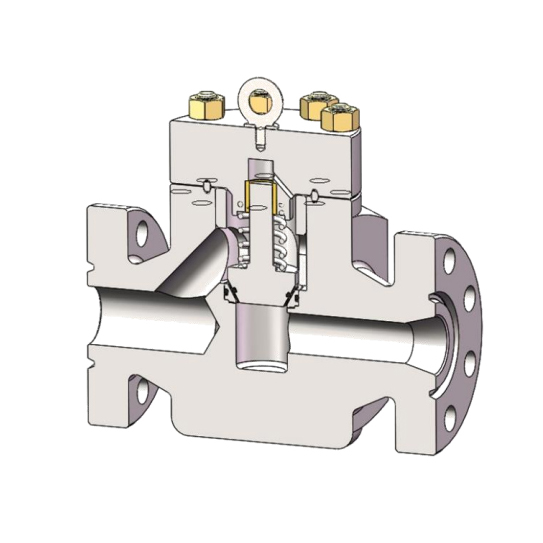

Lift type

The lifting check valve is a one-way check valve, when the medium flows in the positive direction, the disc opens under the action of fluid pressure;

When the medium flows in the opposite direction, the disc closes under gravity and reverse fluid pressure, truncating the channel.

The valve adopts a lifting structure, which is not limited by the installation direction. The valve body and bonnet are sealed with metal gaskets.

Safe and secure. The sealing surface of the valve disc and valve seat are made of Sitaili cobalt-based carbide overlay welding, which has high hardness and wear resistance

Corrosion resistance, good anti-friction performance, long life. After grinding, the surface finish is extremely high, and the sealing is stable and reliable. Disc

The front cone sealing surface is automatically aligned with the valve seat. When sealing, the fluid itself is used to return pressure, and the return pressure is denser

The better the sealing performance.

The lifting check valve has a large resistance and is generally installed on the conventional well well pipeline.

Features

1.Working Pressures : 5000-15000psi

2.Material Level : AA- FF

3.Production Spec Level :PSL1-4

4.API Temperature Rating :-29~121℃

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141