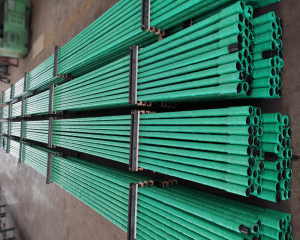

Products

API standard oil pump

Product Specification

1. API standard oil pump is general international oil field pump type, mainly divided into two major categories:tubing pump and rod pump.

In the inspection and maintenance pump, it can directly pull out of the pump or valve to ground, without moving the tubing string.

2.Rod pump is equipped with a support joint, support joint connected on the tubing string, and it is together with the tubing string down to the bottom. Plunger assembly is connected on the rod string and together with the whole pump down to support joint position, pump is fixed within the support joint by external force, plunger assembly is together with the sucker rod string up and down reciprocating movement to achieve pumping work.

When inspection and maintenance pump,it need not to put out of the tubing string, only through rod string together put out of the whole pump, operation is simple.

API-RHAC, Rod, Heavy Wall Barrel, Cup Top Anchor Pump

Rod pump are suspended inside the tubing with

the support joint ,it is suitable for low temperature of

deep well and deviated well drilling, good corrosion

resistant effect. easy to operate,

economical and practical, it can reduce oil field

operation cost by more than 50%.

It can be designed according to the customer’s well

|

Model |

mm(in)Nominal Dia. |

m(ft)Plunger Length |

Stroke m |

m3/d Pump Constant |

Tubing And Thread |

In Sucker Rod |

|

20-125RHAC/M |

32(1.25) |

1.2-1.8 (4-6) |

≤7.5 |

1.14 |

2⅜ |

¾ |

|

25-150RHAC/M |

38(1.50) |

1.64 |

2⅞ |

¾ |

||

|

25-175RHAC/M |

44(1.75) |

2.24 |

2⅞ |

¾ |

||

|

30-225RHAC/M |

57(2.25) |

3.69 |

3½ |

¾ |

||

|

20-125RHBC/M |

32(1.25) |

1.14 |

2⅜ |

¾ |

||

|

25-150RHBC/M |

38(1.50) |

1.64 |

2⅞ |

¾ |

||

|

25-175RHBC/M |

44(1.75) |

2.24 |

2⅞ |

¾ |

||

|

30-225RHBC/M |

57(2.25) |

3.69 |

3½ |

¾ |

||

|

20-125RHTC/M |

32(1.25) |

1.14 |

2⅜ |

¾ |

||

|

25-150RHTC/M |

38(1.50) |

1.64 |

2⅞ |

¾ |

||

|

25-175RHTC/M |

44(1.75) |

2.24 |

2⅞ |

¾ |

||

|

30-225RHTC/M |

57(2.25) |

3.69 |

3½ |

¾ |

3.The workover process of tubing pump is: firstly the barrel being connected to the tubing is directly run into the well at desired depth and then the plunger is run into the barrel with the sucker rod. The applicable tubing pump is larger in size than rod pump in the same tubing. Tubing pump has simple structure so the displacement is bigger and it is suitable for the shallower well with shallow depth and high production.

The THD type of tubing pump means that its standing valve is directly connected to the barrel and it cannot be pulled up separately with the barrel. The THC or THM type of tubing pump means that its standing valve can be pulled up separately with the barrel. The seating assembly of THC pump is cup type and for THM is mechanical type. The THC and THM type of tubing pump are suitable for the frequently work-over wells

Specifications Of Tubing Pumps

|

Model |

mm(in)Nominal Dia. |

m(ft)Plunger Length |

Stroke m |

m3/d Pump Constant |

Tubing And Thread |

In Sucker Rod |

|

20-125TH |

32(1.25) |

1.2-1.8 (4-6) |

0.6-7.3 |

1.14 |

2⅜NU/EU |

¾ |

|

25-125TH |

32(1.25) |

0.6-7.3 |

1.14 |

2⅞NU/EU |

¾ |

|

|

20-150TH |

38(1.50) |

0.6-7.3 |

1.64 |

2⅜NU/EU |

¾ |

|

|

25-150TH |

38(1.50) |

0.6-7.3 |

1.64 |

2⅞NU/EU |

¾ |

|

|

20-175TH |

44(1.75) |

0.6-7.3 |

2.24 |

2⅜NU/EU |

¾ |

|

|

25-175TH |

44(1.75) |

0.6-7.3 |

2.24 |

2⅞NU/EU |

¾ |

|

|

25-225TH |

57(2.25) |

0.6-7.3 |

3.69 |

2⅞NU/EU |

¾ |

|

|

30-275TH |

70(2.75) |

0.6-7.3 |

5.50 |

3½NU/EU |

⅞ |

|

|

35-325TH |

83(3.25) |

0.6-7.3 |

7.70 |

4NU/EU |

⅞ |

|

|

40-375TH |

95(3.75) |

0.6-7.3 |

10.26 |

4½NU/EU |

1 |

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141