Products

API 11D1 Dissolvable Frac Plug for Hydraulic fracturing

Single Slip Dissolvable Frac Plug

• Large inner diameter, 50%-80% larger than conventional plugs.

• Dissolvable ring replaces traditional dissolvable cylinder, reducing volume by 90%.

• Compact structure with integrated anti-premature seating design.

• Short length for easier insertion in deformed wellbore conditions.

• Small size, fast dissolution rate, low residue.

| Temperature classes | Formation temperature | Dissolve time(Related to temperature and liquid salinity) |

| High temperature | 90℃~120℃ | 2~5 days |

| Medium temperature | 60℃~90℃ | 2~5 days |

| Low temperature | 25℃~60℃ | 3~7 days |

| CSG parameters | Dissolvable frac plugs parameters | ||||

| csg size | csg weight | csg ID | Max OD | Min ID | length |

| in. (mm) | Lb/ft | in. (mm) | in. (mm) | in. (mm) | in. (mm) |

| 5.5(139.7) | 17~20 | 4.778~4.892(121.36~124.26) | 4.409(112) | 2.48(63) | 13(330) |

| 20~23 | 4.670~4.778(118.62~121.36) | 4.331(110) | 2.48(63) | 13(330) | |

| 23~26.8 | 4.500~4.670(114.3~118.62) | 4.134(105) | 1.811(46) | 13(330) | |

| 3.898(99) | 1.378(35) | 15.51(394) | |||

| 5(127) | 21.4 | 4.126(104.8) | 3.752(95.3) | 1.811(46) | 12.48(317) |

| 4.5(114.3) | 11.6 | 4(101.6) | 3.752(95.3) | 1.811(46) | 12.48(317) |

| 13.5~15.1 | 3.826~3.920(97.18~99.56) | 3.583(91) | 1.811(46) | 12.36(314) | |

| 3.5(88.9) | 9.2~10.2 | 2.922~2.992(74.22~76) | 2.64(67) | 0.945(24) | 12.31(312.75) |

Double Slip Dissolvable Frac Plug

• Traditional frac plug structure design, two-way slip and compression type of large rubber tube, more solid anchoring, better sealing performance

• The range of temperature adaptation is wider

• Small outer diameter design, easier to run in casing deformation conditions

• Low residue

| Temperature classes | Formation temperature |

Dissolve time (Related to temperature and liquid salinity) |

| superhigh temperature | 120℃~185℃ | 3~5 days |

| High temperature | 90℃~120℃ | 4~6 days |

| Medium temperature | 60℃~90℃ | 4~6 days |

| Low temperature | 25℃~60℃ | 5~8 days |

| CSG parameters | Dissolvable frac plugs parameters | |||||||

| csg size | csg weight | csg ID | Max OD | Min ID | length | |||

| in. (mm) | Lb/ft | in. (mm) | in. (mm) | in. (mm) | in. (mm) | |||

| 5.5(139.7) | 17~20 | 4.778~4.892(121.36~124.26) | 4.45(113) | 1.378(35) | 23.62(600) | |||

| 20~23 | 4.670~4.778(118.62~121.36) | 4.33(110) | 1.378(35) | 23.62(600) | ||||

| 23~26.8 | 4.5~4.670(114.3~118.62) | 4.055(103) | 1.378(35) | 22.32(567) | ||||

| 23~29.7 | 4.376~4.670(111.2~118.62) | 3.897(99) | 1.181(30) | 22.32(567) | ||||

| 26.8~29.7 | 4.376~4.5(111.2~114.3) | 3.74(95) | 1.181(30) | 22.32(567) | ||||

| 5(127) | 21.4 | 4.126(104.8) | 3.675 (93.35) | 1.181(30) | 21.97(558) | |||

| 4.5(114.3) | 11.6~13.5 | 3.92~4(99.57~101.6) | 3.675(93.35) | 1.181(30) | 21.97(558) | |||

| 13.5~15.1 | 3.826~3.920(97.18~99.57) | 3.6(91.44) | 1.181(30) | 21.97(558) | ||||

| 13.5~15.1 | 3.826~3.920(97.18~99.57) | 3.5(89) | 1.181(30) | 22.22(564.5) | ||||

| 3.5(88.9) | 9.2~10.2 | 2.992~2.922(76~74.22) | 2.66 (67.56) | 0.95(24.13) | 437(17.20) | |||

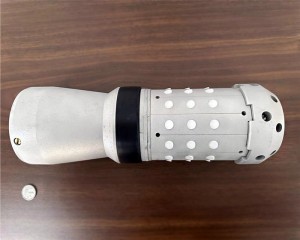

Metal Seal Dissolvable Frac Plug

• Unique metal seal ring design, all metal seal, no rubber parts

• Extra-large inner diameter, 60% larger than conventional plug

• Compact structure, integrated anti-early setting design

• Shorter length, easier to run in casing deformation conditions

• Small volume, quick dissolution, low residue

• The range of temperature adaptation is wider

| Temperature classes | Formation temperature |

Dissolve time (Related to temperature and liquid salinity) |

| High temperature | 90℃~120℃ | 2~5 days |

| Medium temperature | 60℃~90℃ | 2~5 days |

| Low temperature | 25℃~60℃ | 3~7 days |

| CSG parameters | Dissolvable frac plugs parameters | ||||||

| csg size | csg weight | csg ID | Max OD | Min ID | length | ||

| in. (mm) | Lb/ft | in. (mm) | in. (mm) | in. (mm) | in. (mm) | ||

| 5.5(139.7) | 17~20 | 4.778~4.892(121.36~124.26) | 4.410(112) | 2.283(58) | 10.24(260) | ||

| 20~23 | 4.670~4.778(118.62~121.36) | 4.331(110) | 2.283(58) | 10.24(260) | |||

| 26.8~29.7 | 4.500~4.670(114.3~118.62) | 4.134(105) | 1.575(40) | 10.24 (260) | |||

| 5(127) | 18 | 4.276(108.6) | 4.028(102.3) | 1.575(40) | 10.24 (260) | ||

| 21.4 | 4.126(104.8) | 3.937(100) | 1.575(40) | 10.24(260) | |||

| 4.5(114.3) | 11.6 | 4(101.6) | 3.752(95.3) | 1.575(40) | 9.84(250) | ||

| 13.5~15.1 | 3.826~3.920(97.18~99.56) | 3.583(91) | 1.811(46) | 9.84(250) | |||

We have API 11D1(V0) and API 14A certification.

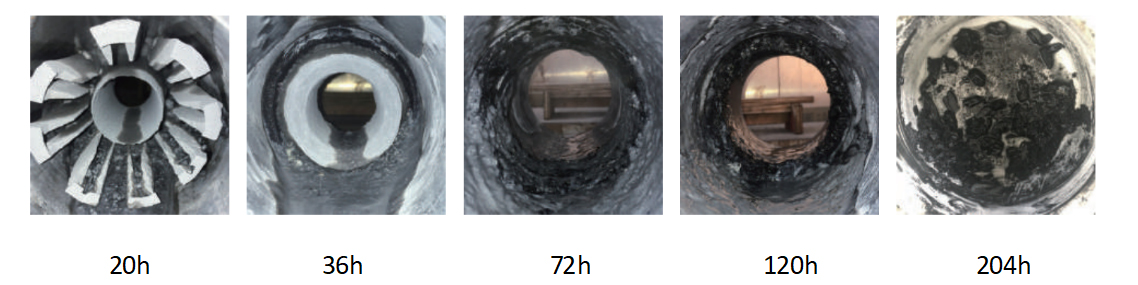

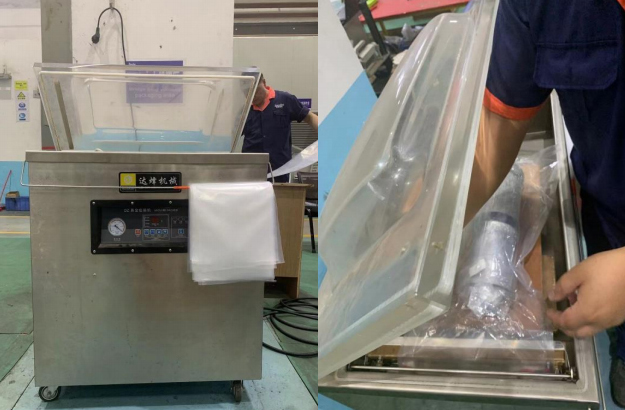

Test results: qualified for immersion, seating seal and pressure resistance, dissolution as shown in the figure.

We have a complete after-sales service and customer training mechanism.

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

Room 703 Building B, Greenland center, Hi-tech development zone Xi’an, China

86-13609153141

86-13609153141